PEX Pipe: Everything You Need To Know

The plumbing system is one of the best innovations in human history. Gone are the days when wastewater travels in the same pipe as potable water, risking contamination and bringing diseases. In recent years, the plumbing industry welcomed developments to create a plumbing material that is both sustainable and durable, thus introducing the PEX pipe.

What is PEX?

People, who are newly acquainted with PEX, often wonder what does PEX stand for? PEX stands for cross-linked polyethylene pipes. They have been making waves in the industry.

So what is PEX plumbing? How does it differ from the old plumbing systems? For the longest time, houses have used lead-based pipes for the plumbing system. Lead-based caused massive health issues such as lead poisoning that led to miscarriages and infant deaths. In the 1800s, the United States shifted to iron plumbing. The shift from wooden log piping to cast-iron piping allowed better pressure regulation and distribution. It was also at this time when indoor plumbing became possible, giving way to the modern plumbing system as we know it now.

Corrosion makes a property prone to water damage. However, throughout the years, people have noticed that cast-iron plumbing is prone to corrosion, especially when the water has high levels of minerals. This translated to costly repairs for a property owner.

By the 1950s, plumbing materials made from plastic made their debut in the market. The choice of material was primarily because of the post-war steel shortage in the US. During this time, polyvinyl chloride or PVC pipes were also introduced. PVC pipes became highly popular, eventually replacing galvanized iron plumbing for residential and commercial areas.

The PEX pipe – also called XPE or XLPE – originated from Europe, where it was primarily used for better heating in chicken farms. When the pipes arrived in the United States, they were used primarily for floor heating systems but immediately gained footing in terms of versatility and workability.

PEX plumbing quickly rose to popularity in recent years as the primary material used for commercial and residential plumbing. The three pipes are PEX-A, PEX-B, and PEX-C. Although there are no significant differences among the three pipes, it is important to note their origins.

PEX-A is developed using the peroxide method, where the cross-linking of the PEX plumbing pipe is done above the crystal melting point. The method of creating PEX-A is longer than the other two pipes because the plastic must be under constant high temperature and pressure.

PEX-B, on the other hand, is developed using the silane method wherein the polyethylene links are formed through silanol condensation. Out of all three varieties of PEX piping, PEX-B is considered to have the least pressure and freezing resistance.

PEX-C is developed by using an electron beam process. The development process of PEX-C is considered the cleanest and most environment-friendly. To create PEX-C, however, a controlled environment is needed.

Old houses are especially vulnerable to water damage. Professional plumbers often advise shifting from traditional copper pipes to a PEX plumbing pipe to prevent damages. But what makes the PEX such a suitable alternative or replacement to galvanized iron or copper? Is it worth the hype? Do these methods of creating these cross-linked pipes prove their durability? Simply put, what is PEX?

General Characteristics Cross-linked Polyethylene Pipes

So what is PEX pipe?

The popularity of the PEX tubing continued to rise at the turn of the decade at around the same time when public consciousness about sustainability rose. Although it will take a long time before every residential area and commercial center uses PEX pipes, the known advantages of switching from old plumbing materials into an entire polyethylene plumbing system make all the difference and convenience in a place’s plumbing system.

1. Color-Coded

One of the advantages of the PEX plumbing pipe is that they come in three colors – red, blue, and white. These colors serve as an indication of the water temperature.

Although there are no differences in materials used for each designated pipe, it has become an industry standard to color-code the piping used to differentiate the water temperature. The red pipes are used for hot water, whereas the blue pipes are generally for cold water. Meanwhile, white pipes are used for either hot or cold water.

2. Flexible Pipe

Unlike the traditional plumbing system, a PEX plumbing pipe is more flexible. With this new plumbing system, installing smaller pipes to the primary water source for each plumbing fixture is no longer necessary. Instead, one flexible plumbing pipe can be connected to the primary water source and pass through floors or walls until it reaches a fixture.

Cross-linked polyethylene pipes, in general, have a uniform size and diameter. However, the tubing size and diameter change depending on the usage. For instance, for the main water line, a tube with a ¾-inch diameter is often used, whereas, for general plumbing, a pipe with a ½-inch diameter will suffice.

A PEX plumbing pipe can come in lengths more than 500 meters which is advantageous over traditional copper and galvanized steel. People can easily buy cross-linked polyethylene piping depending on the length needed. The purpose of long lengths for these pipes is especially for manifold-based plumbing systems.

3. No Soldering Required

Galvanized steel, copper, and cast-iron pipes require soldering smaller parts into the main water supply to transport water to each plumbing fixture properly.

The flexibility of the PEX plumbing allows it to fit easily with minor adjustments to the main pipe. Cross-linked polyethylene only requires the right “fittings” to fasten each pipe to the water supply correctly.

fittings connect cross-linked polyethylene pipes: push-fit, crimp, clamp, and thermal expansion.

Push-fits are plastic PEX fittings that are easily connected by “pushing in” the PEX fittings without the help of fastening tools. On the other hand, connecting pipes through crimps involves using brass fittings and copper rings. These copper rings are slid through on the pipe while the brass fitting fits the pipe opening. A crimp tool is used to fasten the copper ring to keep the brass fitting in place.

Clamping pipes are quite similar to crimps. Clamp rings encircle the pipe while a fitting is placed inside the tube. A clamping tool is then used to fasten the clamp rings and secure the PEX pipe fittings.

Although the thermal expansion method of connecting the pipes is a more complicated process than the first three, the process is still quite easy. In the thermal expansion method, a heat gun is used to expand the edge of a pipe to insert the fitting easily. As the pipe cools down, it slowly fits the mold of the PEX fittings used.

4. Pipe Expansion

Although cross-linked ethylene pipes can withstand harsh temperatures, plumbing professionals would like to clarify that they are not freeze-proof. The chemical composition of these polyethylene pipes allows them to expand in low temperatures. This means that there will be little to no damage to the pipes when winter comes, preventing leakage and property flooding.

To prolong the life of polyethylene tubing, observing pre-winter precautions is still necessary. Dedicate the autumn season to preparing the plumbing system to minimize the stress towards the new PEX water pipe. This is why even though this durable piping system can easily expand to accommodate freezing water, it is still important to keep the whole system insulated.

5. Silent Water Transport

A loud banging sound is common with galvanized steel and copper pipes. This is what plumbers call a “water hammer.” This phenomenon is considered a hydraulic shock when the shut-off valve within a high-pressure system suddenly closes. Water hammer can be unpleasant to hear and, when not resolved, can eventually cause damages to the plumbing system.

Using cross-linked polyethylene pipes lessens the water hammer noise because of their general composition of a pressure-resistant, flexible water line.

Advantages of Shifting to Cross-Linked Polyethylene Pipes

The plumbing industry welcomes the possibility of the widespread use of cross-linked ethylene pipes for both commercial and residential systems. Before entirely shifting to this newer plumbing system, there are considerations to be made.

Cross-linked polyethylene pipes have a lot of advantages over traditional piping systems. Here are the main reasons more people are replacing their old plumbing system with new PEX/XPE pipes.

1. Sustainability

Polyethylene pipes have become popular over recent years because they provide a more affordable and sustainable alternative to galvanized steel, copper, and cast-iron.

According to an earlier study published in 2016 by the Journal of Cleaner Production and a follow-up by the European Plastic Pipe and Fittings Association, using cross-linked polyethylene pipes instead of copper reduces overall construction cost. Moreover, polyethylene pipes show that they can be installed 30% faster than other pipe materials and are proven to prevent leaks by up to 75%. They also display longevity of use and excellent resistance against corrosion.

These polyethylene pipes are durable and flexible, making them less susceptible to corrosion. This is why cross-linked polyethylene pipes last longer than galvanized steel or copper. Buildings that use PEX tubing save more money in terms of damage repair.

2. Prevents Winter Water Damage

Do PEX pipes freeze? This is one of the common questions asked when switching from traditional plumbing.

Winter is stressful for the plumbing system, especially in residential areas. When a house employs a plumbing system made of copper or cast-iron, it is prone to winter water damage and flooding. Homeowners have to prepare the whole system for the arrival of below-zero temperatures to prevent cracks and leakage.

When water freezes, its particles trigger high water pressure, which can cause cracks in a piping system. Once the water melts, the cracks may eventually lead to leakage. Using a PEX plumbing system prevents this damage because the pipes are developed to expand even at lower temperatures and deal with high water pressure. Does PEX pipe freeze? The answer is yes. But it has a higher resistance to freezing than copper or steel.

3. More Room For DIY

The flexibility of PEX piping encourages amateur plumbers to experiment and learn. Plus, complicated processes like brazing and soldering are not entirely required with PEX piping systems, making it easy for amateurs to understand how general plumbing works.

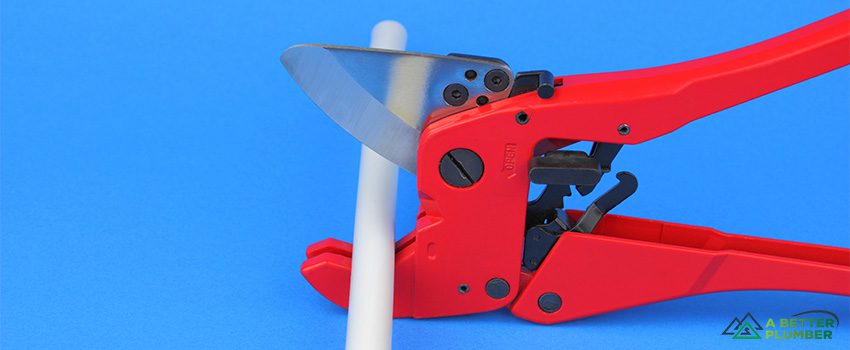

Cross-linked polyethylene pipes are relatively inexpensive, which makes them accessible for beginners. Another factor that makes cross-linked polyethylene tubing perfect for beginners is that it is quite soft compared to PVC and copper pipes. The material’s relative softness makes it easy to cut without using industry-grade cutters.

Frequently Asked Questions Regarding PEX Plumbing Systems

If you are considering switching to a polyethylene plumbing system yet are not yet fully convinced of the safety and other factors, maybe these answers to the common questions can help you decide.

1. How is a PEX system installed?

There are several techniques on how to install PEX pipe depending on the materials that are used with the polyethylene piping. However, in general, installing cross-linked polyethylene pipes does not need soldering. Instead, only the right fittings are needed to install and fasten the pipes to each other.

Push-fits are commonly used for general plumbing, like additional connections for a bathroom. However, a more durable installation is needed for commercial buildings, especially those that require massive water usage, like restaurants.

It is important to note what plumbing project is being done to assess the workload properly, the materials used (manifolds, crimp fittings, etc.), and the time that needs to be allotted to accomplish the said project. Everything begins with good planning to install these cross-linked polyethylene pipes efficiently. For commercial buildings, it is vital to choose the materials wisely. Avoid massive water damage by using crimps and clamps to install the pipes to the main water supply.

Once the plan is completed and the necessary tools are gathered, it is time for the installation.

Step 1: Cut the pipe accordingly. Step 2: Put the PEX crimp over the tube at two inches from the edge of the pipe. Step 3: Insert PEX pipe fittings into the pipes. Step 4: Position the PEX crimp near the edge of the pipe. Give a ¼-inch allowance from the end of the pipe. Make sure that the crimp is above the fitting barbs. Step 5. Using a crimp tool, fasten the crimp ring at a 90-degree angle on the pipe.2. Is PEX safe for drinking water?

The safety of using polyethylene piping for drinking water is a valid concern, especially since it was proven that plastic releases substances that may contain toxic materials and highly-carcinogenic elements.

A recent study shows that there are brands of cross-linked polyethylene piping that exhibit leaching 62 types of chemicals into the water. Although these chemicals can be considered toxicological, they are not carcinogenic. However, this study is not definitive proof of the safety of the pipes since widespread usage only began recently. In conclusion, cross-linked polyethylene piping is good for the plumbing system in general, especially for heating, but caution is advised when connecting pipes for potable water.

Research and development are still on their way to discovering the maximum potential of cross-linked polyethylene pipes. The recent years brought discoveries on its possible weaknesses and risks. More manufacturers are optimistic about developing a sustainable and inexpensive material that will improve the plumbing system, especially now that the popularity of cross-linked polyethylene pipes has begun to change the commercial construction industry.

Plumbing professionals predict that more commercial areas and businesses will shift towards PEX-based plumbing systems. Since cross-linked polyethylene tubing is inexpensive, professionals believe it will encourage people to shift from traditional plumbing materials. Plumbing professionals also believe that increasing demand for these pipes will result in more research and innovations for the industry.

Absolute Electrical Heating and Air Helps You With Everything Your Plumbing System Needs

Looking for a professional plumbing service that can give you great advice on maintaining your plumbing system?

Absolute Electrical Heating and Air is your best bet! With ten years of plumbing experience, Absolute Electrical Heating and Air provides excavation, drain cleaning, and general plumbing issues. Our team provides an accurate sewer camera for residential areas that checks a sewage system’s general situation and condition.

Absolute Electrical Heating and Air employs professionals who are well-equipped with the necessary skills and knowledge of the latest trends and technology in the plumbing industry. The next time you need a plumber in Denver, contact Absolute Electrical Heating and Air for an affordable and effective plumbing service.

CONTACT US

Request Service

Save Every Year with an Absolute Advantage Membership

Expert Annual System Safety Inspections & More

- Priority service

- Waived dispatch fees

- Yearly furnace, A/C, & electrical system inspections

- 10% discount on repairs and additional diagnostic services

- Up to $500 off HVAC & electrical panel replacements